Heat Exchangers 101

Almost all food and beverages on today's shelves were produced with the help of a heat exchanger. This important piece of equipment not only helps plants meet regulatory requirements, but it helps make food safe to store and eat.

If you're not familiar with plate heat exchangers (PHEs) or their intricate parts, consider this your crash course.

Chapter 1: Heat Exchangers

What Is a Heat Exchanger?

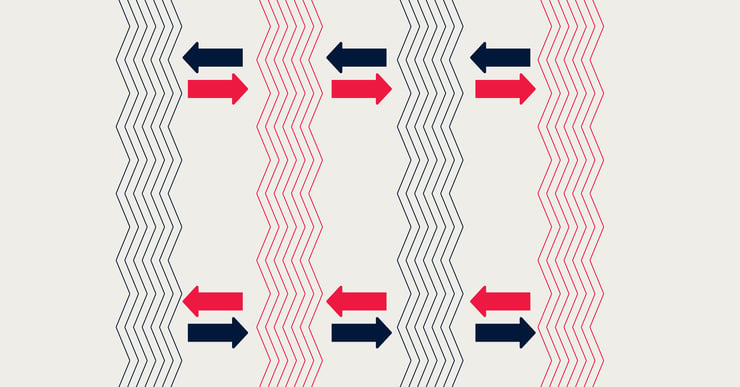

The main function of a PHE is to transfer heat between two fluids that are at different temperatures. Heat is transferred from a hot medium to a cold medium to make foods and beverages through pasteurization, sterilization, and other hygienic processes. Through an arrangement of parallel flow channels (alternating hot and cold fluids), the product comes into contact with the surface of the alternate plate. As product moves through the equipment, heat is transferred to bring the product to a designated temperature.

Why Are Heat Exchangers Necessary?

Food and beverage products need to be heated in order to reduce the bacteria load based on a specified log reduction. A PHE assists this process by transferring a thermal BTU load from one media to another. With a PHE, one fluid on either side of a plate transfers BTU loads to the other, thereby heating the product to a designated temperature.

Heat exchangers are also necessary for cooling down products prior to storage. Through this process, plants can prevent an existing bacteria load from growing, thereby extending the product's shelf life.

Application of Heat Exchangers

Many industries use heat exchangers to produce safe food products, including:

AGC's heat exchangers can handle a variety of viscosities and food products — and they can also be used for utility applications.

In fact, AGC was also recently called upon to help a small startup, Noya, with their sustainability mission: to capture CO2 in the air and repurpose it. Our heat exchanger is used in Noya's cooling tower to heat the water and contribute to the overall process of regenerating CO2 in its pure form so it can be repurposed.

What is the Heat Exchange Process?

With a PHE, product enters the heat exchanger through an inlet and comes into contact with stainless steel plates, which are hung side-by-side within the frame. The space between these plates, also known as channels, alternate with product (which enters the PHE to change temperature) and media (used to change the product's temperature), allowing two counter-current mediums to flow through the PHE without making contact. By introducing one cold-flowing medium and one hot-flowing medium into these alternating channels, PHEs can exchange BTUs between mediums, resulting in the desired temperature.

For example, a dairy plant might use hot water to raise the temperature of milk during the pasteurization process. Hot water and cold milk will flow through the PHE, alternating channels, allowing the cold milk to be brought up to a designated temperature with the aid of the hot water on the other side of the plate, with the two fluids never mixing.

What is Pasteurization?

No matter what medium is going through the heat exchanger, the principle of pasteurization is the same.

Pasteurization is used to eliminate potentially harmful pathogens to help keep dairy products safe for consumption and extend shelf life. Today, pasteurization is a standardized process. Unpasteurized dairy can contain harmful bacteria that can lead to serious illness. The pasteurization process heats dairy products for a determined time to a specific temperature that reduces the presence of harmful bacteria.

Pasteurization and sterilization differ slightly in the amount of bacteria that remain in the product after the process. With sterilization, the bacteria load is eliminated completely. With pasteurization, bacteria is reduced to an acceptable, healthy level, as indicated by the Pasteurized Milk Ordinance.

Types of Heat Exchangers

There are three main types of heat exchangers used for food production:

- Plate and frame

- Shell and tube

- Scraped surface (used for high-viscosity products, such as cream cheese)

Why Use a Plate Heat Exchanger?

PHEs offer several unique key features:

Efficiency

Many plants have existing BTUs lying around their plant that can be used to preheat their product so that it's ready for the next step in production. For example, if a plant utilizes hot process water, it can be used on the media side of the permeate to preheat the product going into the evaporator. By repurposing BTUs, plants can save energy and money.

PHEs are also the most efficient way to accomplish the task of transferring BTUs from one media to another. The plates in PHEs are thin with a large surface area, supporting thermal transfer. The channels between plates (also referred to as clearance) are also very thin, helping to ensure maximum surface contact. And the corrugations on the plates help minimize fouling and promote turbulent flow to maximize uptime.

Easy to Maintain

With a PHE, you can open, inspect, and replace consumable parts. This makes them easier to maintain and service, which extends the life of your heat exchanger.

Customizable

Besides being easier to maintain, PHEs are also modular, customizable, and versatile. By providing your product for rheology testing, AGC can create a PHE that can support many products, viscosities, and production volumes.

If you're trying to choose the right heat exchanger for your needs, know that every user's needs are unique, and therefore there is not a one-size-fits-all model. As a result, AGC custom builds heat exchangers to work with each plant's unique product and footprint.

What is the Purpose of a Hydraulic End on a Heat Exchanger?

A hydraulic PHE is a huge time saver for industries like the dairy and egg industry and plants that are required to open their PHE on a frequent basis. Manually opening a PHE can create hours of unnecessary downtime and labor. The hydraulic end of a heat exchanger allows users to open and close the PHE within minutes with just the push of a button.

Chapter 2: Heat Exchanger Parts

What Are the Parts of a Heat Exchanger?

PHEs have many parts, including:

- Fixed frame: This is a fixed end. The frame may include a hydraulic unit if it's a hydraulic PHE.

- Follower: This piece crunches the plates together.

- Top rail: Where the plates hang from.

- Plates: Plates are usually made from stainless steel, due to the material's ability to withstand high temperatures and its resistance to corrosion. Plates are typically 0.5-0.7 mm thick, with thicker plates more durable and less likely to bend. Each plate hangs within the PHE on the plate hanger (situated beneath the top rail), with gaskets creating channels between the plates. Plates are locked together using alignment devices. Corrugations on the plates help ensure a turbulent flow through the heat exchanger.

- Gaskets: Attached to the plate, rubber gaskets seal the channels between each plate, leaving a small gap (or clearance) between each plate for the product to flow through.

Heat Exchanger Replacement Parts

Your PHE plates and other parts can last a long time with just a few easy preventative maintenance measures. However, your heat exchanger will inevitably show some wear and tear.

If you notice that your heat exchanger's efficiency is decreasing, you might want to consider replacing some of its parts by upgrading to custom parts that are designed for your specific production line. Custom parts will help maintain efficiency across your facility because they are specifically designed with your production goals in mind.

If you want to optimize your system's efficiency, you don't have to look at replacing your whole system. AGC has the largest stock of PHE Original Equipment Manufacturer (OEM) and aftermarket plates and gaskets to create a customized plate pack made specifically for your needs and goals. Customizing your plate pack also maximizes your production speeds, supports the effectiveness of your cleaning and maintenance schedule, and can impact your bottom line.

Whether AGC sold you your PHE or not, we can offer your plant parts that will seamlessly work with most systems without the wait times that often come when working with other OEMs. You'll also get top-of-the-line service from our service techs who can help you solve your PHE problems quickly so you're back up and running in no time.

Chapter 3: Heat Exchanger Troubleshooting

Easy Ways to Prevent Plant Downtime

When your heat exchanger is down, your whole plant is down. That's why it's vital to perform preventative maintenance to keep your equipment running correctly. Here are some easy ways to maximize your plant's uptime.

Keep Spare Parts on Your Shelf

Having spare parts at the ready means less downtime at your plant. For example, if you dead stop a valve and you back-pressure your PHE, you could easily blow a gasket. This gasket is the first point of failure for your PHE. If you don't have a spare at the ready, you could lose days of production versus a few hours.

AGC always sends a list of recommended spare parts to stock with every PHE so you have the most common replacement parts you'll need based on your unit or the size of your unit.

For example, we recently worked with a company that produced insulin with their heat exchanger in a pharmaceutical application. Naturally, with such an important medication being made, the company couldn't afford much downtime.

When the company's PHE began to malfunction, they called us immediately to consult our service team. Their unit was 11 years old and had never been inspected by AGC before. We worked with their local PHE service distributor to evaluate the PHE and diagnose the issue and discovered that the PHE ended up needing a new plate pack.

At the recommendation of our partner distributor, we were able to pull a plate pack together to fit their equipment and next-day air shipped it to the plant so we could get them back up and running. Our tech also flew to the plant and was able to switch out the plate in just a few hours.

A lot of expense and downtime could have been avoided with spare parts on hand and regularly scheduled preventative maintenance. Luckily, we had what this plant needed in stock, but an annual maintenance check would have helped them avoid the extra cost and lost time.

Perform Adequate Inspections and Preventative Maintenance

Without regular maintenance, it's possible you may open your PHE one day and discover that all of the gaskets are shot — or that your plates have experienced a lot of fouling. Even if you replace these parts, you may find that they can't get your equipment back together properly, or that your equipment is no longer functioning as it should with your projected production volume.

Preventative maintenance helps you stay on top of these issues before they force you to stop production and create unnecessary downtime.

Open Your PHE Frequently

Opening and inspecting your PHE could tell you if your plate was installed incorrectly, if the wrong plate is in the wrong spot, or if there's a fouling issue you didn't know about. Without visually inspecting the inside of your heat exchanger, your PHE may lose efficiency and won't be able to do its job.

Don't Change Product Composition Without Rheology

When you send in samples for rheology, we can help make sure that your PHE is properly designed for your new product composition. With AGC, this service is free of charge.

Check Your Gaskets Frequently (and Replace Them as Needed)

Gaskets are the most consumable part of a PHE — and as a result, it's important to keep an eye on their wear and tear. Gaskets should be inspected frequently, as a loss of integrity in a gasket can lead to leaks and cross-contamination between the two mediums flowing through the PHE.

How Can Plants Troubleshoot Heat Exchanger Issues on Their Own?

When something goes wrong and time is of the essence, it's best to consult with AGC to help you get up and running quickly and efficiently. However, there are some easy steps you can take to prevent catastrophe and extend the life of your plates as much as possible. These include:

- Practice recommended clean-in-place (CIP) measures

- Adhere to regular preventive maintenance

- Request a free rheology analysis

- Keep records for ease of audits and future planning

Chapter 4: Why AGC?

At AGC, we pride ourselves on the relationships we have cultivated with our customers over the years. Our customer service and expert staff have helped us become one of the leading suppliers of PHEs in North America.

AGC offers services that range from installation, replacement parts, plant staff training, regular maintenance to extend the life of your PHE, and more. And the best part is AGC is quick and knowledgeable so that if disaster strikes, you won't lose a lot of time looking for the right help to get your plant back up and moving again.